Stanford University

Using computers for manufacturing

Year

2013

Role

Designer

Timeframe

2 months

Summary

This was created at Stanford University for a class using the CNC mill. I chose to design a chess set to take advantage of the CNC mill's capability to automate a large part of the manufacturing process, making it easier to create more than one of the same object.

The idea for the design was to rethink the aesthetics of a chess set. I sought to make the pieces more organic, abstract forms, while still maintaining their original identities. I saw inconsistency between the traditional chess sets, so I wanted to create harmony between the pieces through shared geometries and curvature.

Creating the designs

I started out by looking at existing chess sets, and getting an idea of what was already out there. I didn't feel like there was always a strong sense of continuity between the pieces:

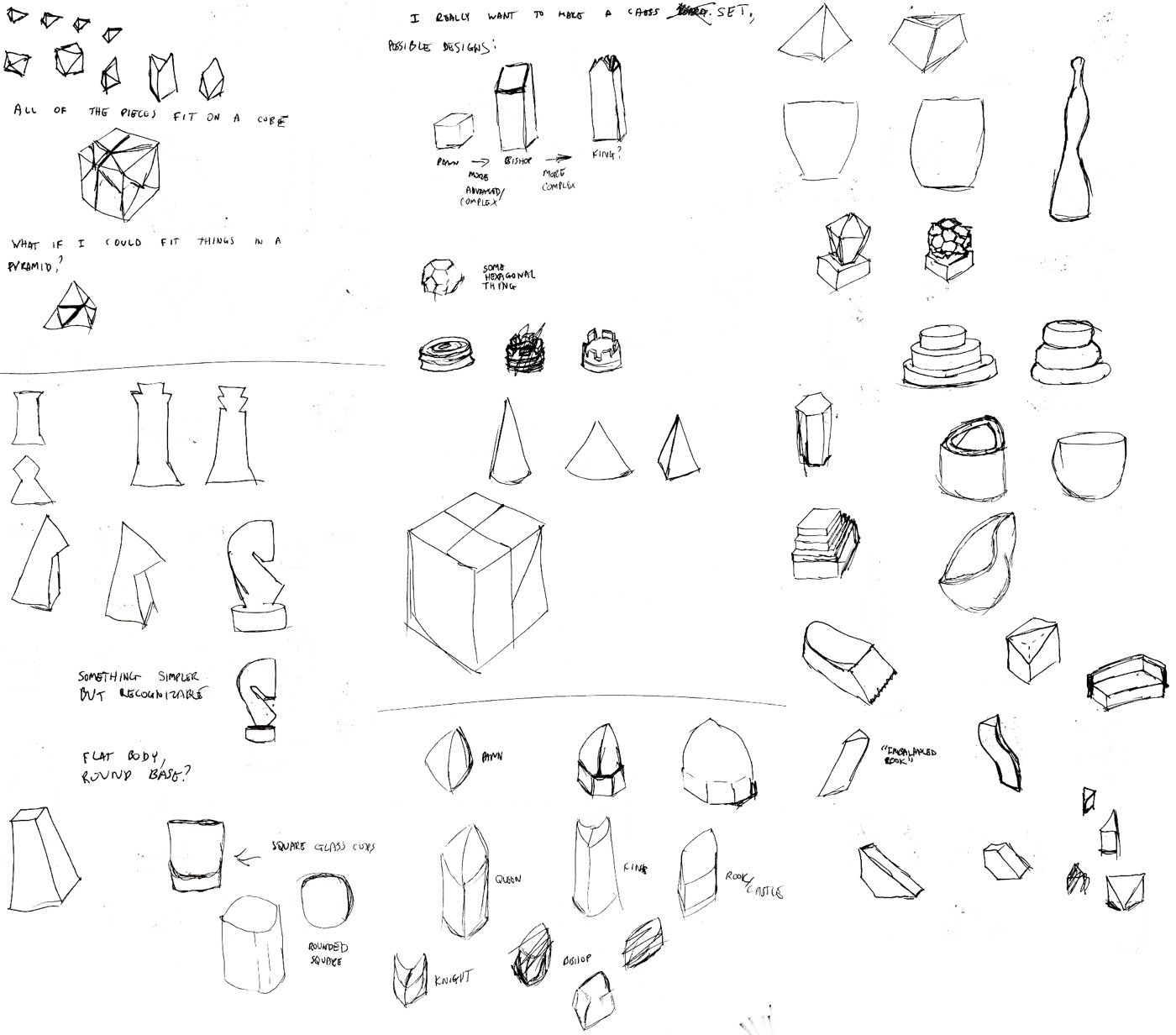

I then began sketching out different shapes and forms until I found a direction with promise.

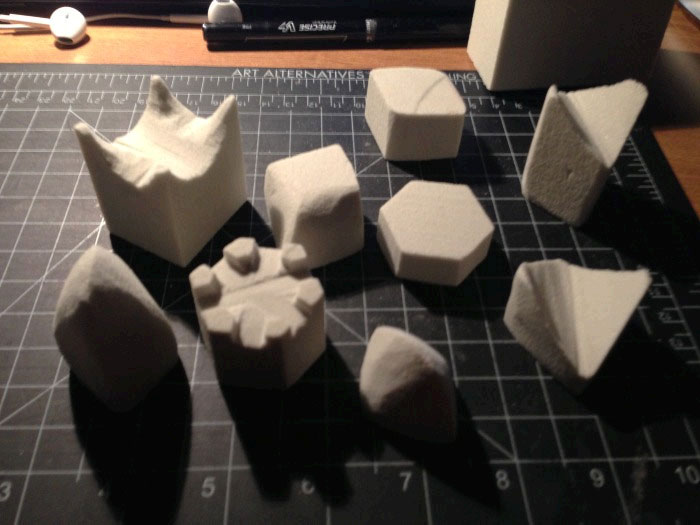

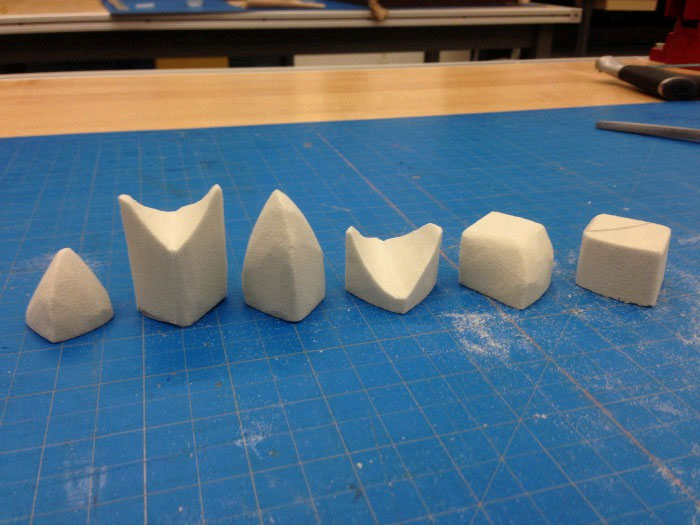

I had started to get some idea of what shapes would be interesting, but the sketches didn't give me the total picture of what it felt like to hold these chess pieces, so I decided to start ideating through carving some foam prototypes.

After finding some shapes I liked, I created the other pieces that would go in the set in foam as well.

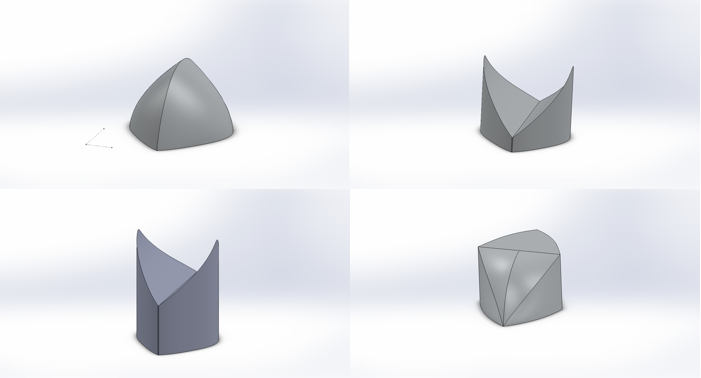

3-D modeling in Solidworks was the next step, where I would get a clear rendering of how the final product would look. During this process, I continued to refine the shape of each piece. Each shape would have the same cross-section when viewed from above, so they would be unified as a set.

The manufacturing process

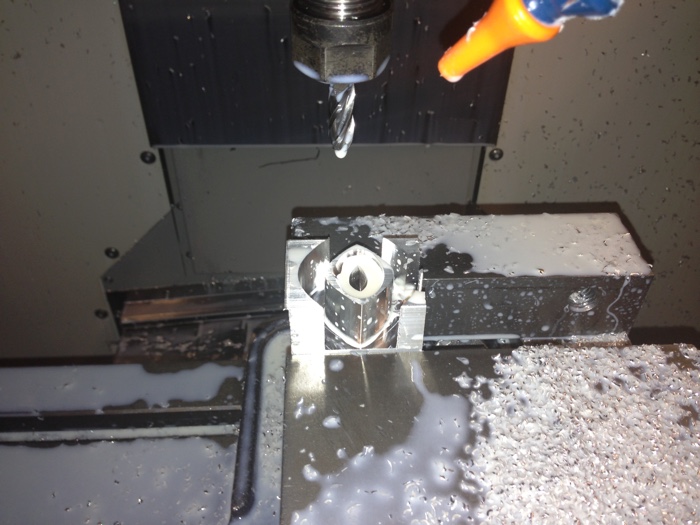

Once the 3-D models were refined and finalized, I wrote the CAM file for each piece, which were the step-by-step instructions that the CNC would interpret and use to start making the pieces. I had to test the CAM file by running the CNC mill without any metal/materials, to see if there were any bugs. Once I was confident that the right instructions were being carried out, I started to machine the individual pieces.

After machining every piece, I sanded them down to smooth out the surfaces and remove marks left from machining.

The final product